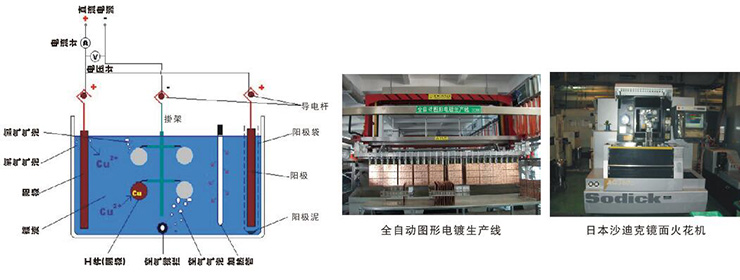

Basic principle of electroplating

Electroplating is an electrochemical process,it's also a REDOX process.The basic process of electroplating is to immerse the part in a solution of a metal salt as a cathode,metal plate as anode,after connecting DC power,the required coating is deposited on the part.

For example:When the nickel plating,the cathode is the part to be plated,the anode is a pure nickel plate,the following reactions occur in the anode and cathode respectively:

Cathode (plated parts):Ni2++2e→Ni (main reaction)

2H++e→H2↑ (side reaction)

Anode (nickel plate):Ni -2e→Ni2+ (main reaction)

4OH--4e→2H2O+O2+4e (side reaction)

Not all metal ions can be deposited from aqueous solutions,if the hydrogenation of hydrogen ions on the cathode is reduced to hydrogen, the main reaction is dominant.Metal ions are difficult to precipitate on the cathode.According to the experiment,Solubility of metal ions from electrodeposition in aqueous solution.

The anode is divided into soluble anode and insoluble anode.Most anodes are soluble anodes corresponding to the coating.For example:Zinc plating for zinc anode,silver plating is silver anode,Tin lead alloy anode for tin lead alloy plating.But a few electroplating is difficult due to anodic dissolution,use of insoluble anode.For example:Acidic gold plating uses mostly platinum or titanium anodes,the main salt ion of the plating solution is supplemented by adding the prepared standard gold-containing solution.The chrome-plated anode uses insoluble anodes such as pure lead, lead-tin alloy, and lead-bismuth alloy.

Basic process

(Polish→buffing)→Hang up→Degreasing, degreasing and wax removal→washing→Acid cleaning activation→(Preplating)→electroplate→washing→(Post-processing)→washing→drying→Hang down→Fuel injection→Inspection and packing

Polish:Remove the grinding lines and all kinds of macroscopic defects on the surface of hardware products,Improve flatness of the part.

Buffing:The purpose of polishing is to further reduce the surface roughness of hardware products,get a bright appearance.Polishing effect is good or bad,directly affect the surface effect of the product.It plays an important role in hardware technology.

Degreasing and degreasing:Remove the surface polishing wax, grease, etc.

Pickling:Remove the rust and oxide film on the surface of the workpiece.Chemical pickling and electrochemical pickling.

Pre-plating treatment:Trimming the hardware surface,remove polishing wax, grease, scale, oxide film, etc. from the surface of the workpiece.Provides a good plating surface for subsequent deposition of plating.Improper pretreatment will affect the bonding strength of the metal plating.It can directly cause peeling and foaming of the plating layer, and can not reach the salt spray time required by customers.Screw teeth are black, black holes in blind holes, etc.70% of galvanized defective products are caused by poor pre-treatment,therefore, pretreatment plays a very important role in the electroplating process.In countries with advanced plating technology,pay great attention to the pre-treatment process.The pretreatment process accounts for half or more of the whole plating process.Therefore, it is possible to obtain a plating layer having a good surface condition and greatly reducing the defect rate.

Fuel injection:Spray a layer of colorless transparent paint for hardware products,protective metal plating,avoid color oxidation,improper handling can cause surface pockmarks, dust spots, hair spots, etc.